Tying machine

Ligatex

Ligatex is a tool for tying plants to the support wires. It is a manual tying machine that performs an automatic tie. Ligatex is comfortable, fast, and cost-effective. It has been used for several years in all major vineyards in France, as well as abroad, in Germany, Italy, and Australia. More comfortable and faster than separate wire systems, lighter, simpler, just as effective, and much more affordable than electric systems. The Ligatex tying machine is 100% made in France.

Its advantages

- It can be operated with one hand, leaving the other free to correctly position the cane.

- With Ligatex, pinching is no longer necessary (so no more risk of tendinitis).

- It is suitable for both left-handed and right-handed users

- It allows working with gloves

Use

The tie is made very quickly in just 3 seconds, with the movement broken down into 3 simple steps:

1

Push

2

Pull

3

Lift

It is very important to perform the movements gently. Simply push forward to the stop, then backward to the stop (a sharp snap as the wire cuts on the backward stop). It is recommended to work smoothly rather than quickly. The tying pliers are to be used exclusively with Ligatex coils.

Maintenance

Ligatex requires no special care but simply to be used normally. There are no systematic wear parts (even the wire cutter shears without cutting; no sharp edge). Just keep it clean and avoid over-greasing. The fully exposed mechanism would then attract all dirt. Lightly grease the friction parts with sewing machine oil or penetrating oil.

Ligatex wire coils

Ligatex wire coils allow for 1100 to 1200 ties with galvanized wire. The tie will gradually degrade to break during the wood pulling operation.

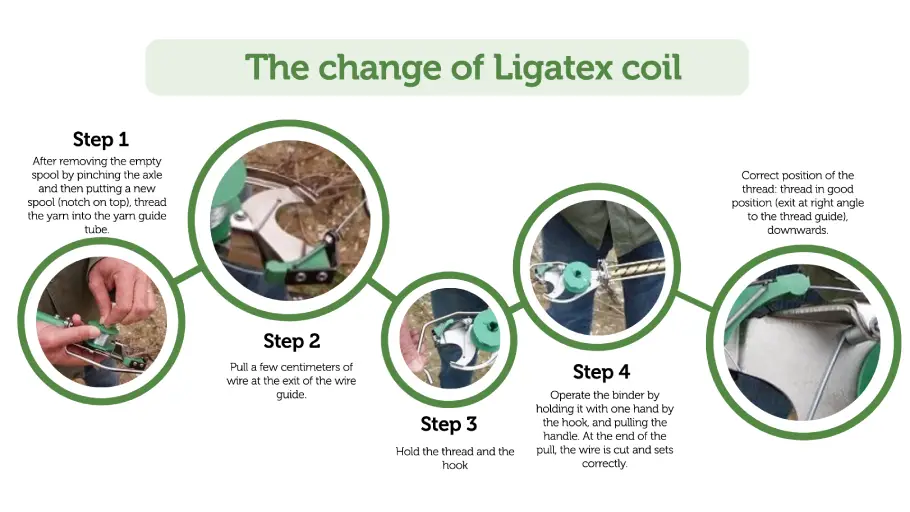

The winding of the coils is specific to Ligatex. If, despite very careful winding, the wire gets stuck, the tie will no longer form. Simply pull 10 cm of wire to pass the blocked area of the coil, then repeat steps 3 and 4 below (run the tying machine “empty” to cut the wire and reset the end in the correct position).

The coils are available in different wire diameters:

- 0.40 mm

- 0.44 mm

- 0.47 mm